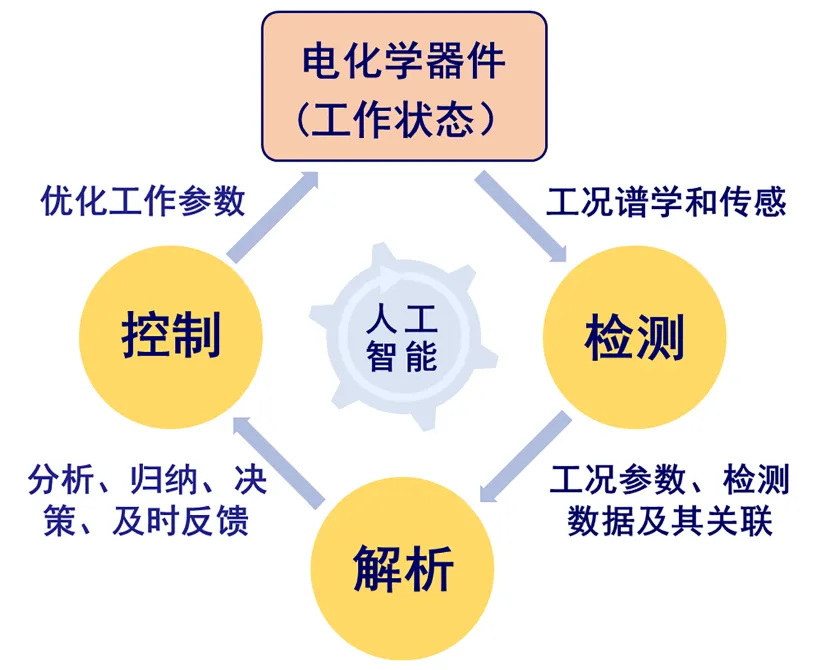

Currently, Xiamen City and Tan Kah Kee Innovation Laboratory are collaborating to build a large-scale smart energy storage infrastructure dedicated to future energy chemistry research, aiming to address numerous scientific and engineering challenges under operational (in situ/operando) conditions. This infrastructure will enable a real-time closed-loop characterization of electrochemical devices through integrated "detection–analysis–control" workflows, with artificial intelligence (AI) models serving as the central "brain" that coordinates detection, analysis, and control. AI4EC Lab is actively collaborating with experimental teams involved in the smart energy storage infrastructure to establish a prototype for achieving this closed-loop research in a specific electrochemical device in the near term, and is providing support in areas such as data collection and AI model development.

To promote new pathways and breakthroughs in AI-empowered spectroscopic characterization under operational conditions, AI4EC Lab hosted a workshop on intelligent spectroscopy. Researchers including Academician Weinan E from Peking University/Beijing Academy of Artificial Intelligence, Academician Zhong-Qun Tian from Xiamen University, Professor Bin Ren (Dean of the College of Chemistry and Chemical Engineering at Xiamen University), Dr. Linfeng Zhang (President of Beijing Institute of Scientific Intelligence), Professor Jun Cheng from Xiamen University, and Dr. Jinghua Tian from Tan Kah Kee Innovation Laboratory participated in discussions.

Professor Jun Cheng, Executive Deputy Director of AI4EC Lab, introduced the lab’s ongoing development of a “Four Beams and N Pillars” framework for electrochemistry. By customizing integrated software-hardware computational solutions, the lab aims to significantly improve the efficiency of high-accuracy first-principles data generation, enabling the construction of large-scale databases for complex material surfaces and interfaces. The goal is to bridge computational and experimental spectroscopic data, and to enable multimodal integration of multiple spectroscopic techniques for real-time analysis of operational characterization data.

Associate Professor Fujie Tang, leader of the Intelligent Spectroscopy team at AI4EC Lab, delivered a detailed report on the spectroscopic intelligent computing initiative. He first outlined the strategy for building spectroscopic models that link microscopic structures to macroscopic spectral data. Electrochemical experiments often involve complex chemical environments with limited and hard-to-obtain experimental data, making it difficult to directly correlate spectra with structural features. Consequently, building AI models that establish "spectrum-structure relationships" directly from experimental data is highly challenging.

To address this, the team proposed starting from computational spectroscopic data combined with high-precision experimental data, as theoretical models can inherently compute spectroscopic signals and automatically associate them with structural information. The team’s approach follows a “three-step roadmap”: beginning with simple model systems to build initial spectroscopic models, gradually introducing chemical complexity, and progressively integrating experimental data to refine the models.

Additionally, he presented the team’s personnel structure and division of responsibilities, and introduced three main categories of spectroscopic characterization strategies—centered on "physical mechanisms," "enhanced clarity," and "experimental data"—to address current challenges in characterizing electrochemical devices. The team proposed solutions including computational spectral decoding, AI-based image analysis, and data-driven methods, aiming to provide comprehensive and diverse support for the smart energy storage infrastructure and its experimental partners.

--

Xu Weihong, head of the engineering team, reported on the planning and progress of experimental data collection. Building large spectroscopic models requires substantial experimental data, making it crucial to establish an experimental spectroscopic database that aligns with computational databases. The engineering team aims to collect high-quality experimental data at scale, using software and hardware engineering solutions to help experimental teams implement automated, standardized, and scalable data acquisition systems—providing robust data support for developing large spectroscopic models. Using automated impedance spectroscopy during battery charge-discharge cycles as an example, the team demonstrated how engineering approaches can solve challenges such as automatic battery sample switching, multi-device coordination, and software automation, thereby achieving fully automated impedance data collection.

Participants engaged in in-depth discussions on multi-level R&D strategies for intelligent spectroscopic computing, team collaboration mechanisms, and integration with real-world systems.

Academician Zhong-Qun Tian emphasized the need to clarify three tiers of spectroscopic applications: (1) acquiring comprehensive, high-quality data on a single system using as many spectroscopic methods as possible; (2) applying key spectroscopic or sensing techniques to obtain data from specific systems relevant to industrialization; and (3) deploying minimal yet effective spectroscopic and sensor technologies directly into real-time industrial operational processes. He urged the team to consider openness in research and identify synergies with other research groups.

Academician Weinan E highlighted the importance of thinking more broadly about model construction and establishing efficient collaboration mechanisms among researchers. Dr. Linfeng Zhang suggested first defining the goals of characterization and control to enable targeted analysis of real-world problems, and to anticipate control algorithms and R&D bottlenecks within the "detection–analysis–control" loop.

Professor Bin Ren pointed out that implementation should address both macro-level parameters supporting industrial applications and micro-level explorations of promising systems. He recommended deriving application-driven research needs from the smart energy storage infrastructure, breaking down complex systems into macroscopic and microscopic challenges, so that collaborative efforts can be coordinated to advance the research cycle. Professor Cheng Wang suggested starting with simulation models to support the validation of specific experimental parameters in engineering processes.

Through this workshop, participants gained deeper insights into AI4EC Lab’s explorations in intelligent spectroscopic computing. The meeting also provided valuable guidance for experimental teams to obtain high-quality, high-throughput spectroscopic data and to advance data-driven research paradigms. Going forward, AI4EC Lab will continue to uphold a collaborative and open philosophy, promoting high-quality and efficient joint research and development. The lab will further advance intelligent spectroscopic computing by developing intelligent computational and analytical platforms for complex electrochemical systems, establishing robust "spectrum-structure" relationship models, and enabling in situ, operational characterization and monitoring of electrochemical devices.